Understanding FIBC Classification: A Complete Guide to Types A, B, C, and D Bulk Bags

Flexible Intermediate Bulk Containers (FIBCs), also known as bulk bags, jumbo bags, or big bags, are a cornerstone of modern industrial packaging. They are widely used across industries such as agriculture, chemicals, fertilizers, food processing, construction, and mining for the safe and cost-effective transportation of dry, flowable products.

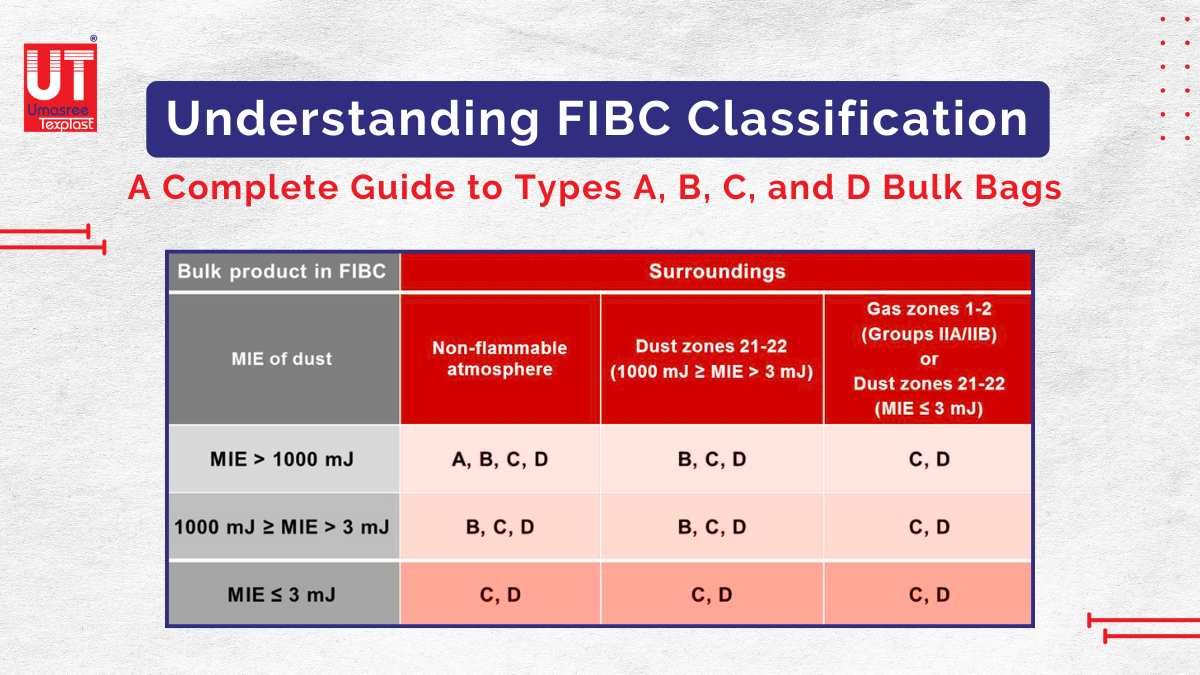

However, not all FIBC bags are the same. One of the most important distinctions lies in FIBC classification based on their electrostatic properties and the level of protection they provide against static electricity. Static buildup during filling, emptying, or transporting bulk materials can be hazardous, especially when flammable powders or gases are present. To address this, FIBCs are classified into Types A, B, C, and D, each designed for specific applications and safety requirements.

In this complete guide, we’ll explain the classification of FIBC bulk bags, their features, uses, and safety considerations.

Why FIBC Classification Matters?

When bulk powders or granules are filled into or discharged from FIBC bags, friction can generate static electricity. If this static is not controlled or safely dissipated, it can cause sparks that ignite combustible dust, gases, or vapors. Choosing the right FIBC bag type is critical to ensuring workplace safety, protecting materials, and complying with industry standards.

The correct bag type depends on:

- The nature of the product (flammable or non-flammable).

- The presence of flammable gases or vapors in the environment.

- The electrical grounding infrastructure of the facility.

Type A FIBCs – Standard Bulk Bags

Type A FIBCs are the most basic and commonly used bulk bags. They are made from plain woven polypropylene or other non-conductive materials without any special electrostatic protection features.

Features

- No protection against static electricity.

- Suitable for non-flammable products.

- Lowest cost option among all FIBC types.

Applications

Type A FIBC bulk bags are safe when transporting non-flammable products such as:

- Sand

- Gravel

- Non-flammable granules or powders

Restrictions

- Cannot be used where combustible gases, vapors, or dust are present.

- Not suitable for flammable products.

Type B FIBCs – Anti-Sparking Bulk Bags

Type B bulk bags are similar in construction to Type A but have materials with a lower breakdown voltage (<6kV). This prevents the occurrence of propagating brush discharges, which can cause explosions in certain environments.

Features

- Provide limited protection against sparks.

- Reduce the risk of energetic discharges.

- Not designed to dissipate static charges through grounding.

Applications

Type B FIBCs are suitable for transporting dry, flammable powders where no flammable gases or vapors are present, such as:

- Flour

- Sugar

- Fertilizers

Restrictions

- Cannot be used in environments with flammable vapors or gases.

- Do not substitute for properly grounded bags.

Type C FIBCs – Conductive (Groundable) Bulk Bags

Type C FIBCs, also known as conductive or groundable bulk bags, are made from interwoven conductive threads. These threads must be electrically grounded during filling and emptying operations. When grounded properly, they safely dissipate static charges.

Features

- Provide a high level of electrostatic safety.

- Require mandatory grounding to function effectively.

- It can be used with a wide range of flammable products.

Applications

Type C FIBC bags are ideal for environments where both flammable powders and flammable vapors or gases are present, such as:

- Chemicals

- Fertilizers

- Dyes and pigments

Restrictions

- Must always be grounded during use.

- Unsafe if grounding is not maintained.

Type D FIBCs – Static Dissipative Bulk Bags

Type D FIBCs are made from static-dissipative materials such as CROHMIQ® fabric. Unlike Type C, they do not require grounding, as the material itself safely dissipates static charges into the atmosphere.

Features

- No grounding required.

- Provide the highest safety for static control.

- Prevent brush and spark discharges even in hazardous environments.

Applications

Type D bulk bags are ideal for the most sensitive and hazardous operations where grounding may not be feasible, such as:

- Environments with flammable powders and flammable vapors.

- Petrochemical and agricultural industries.

- Operations with strict safety regulations.

Restrictions

Must not be used with bags that are contaminated with conductive materials (such as grease or oil).

Quick Comparison of FIBC Types

| FIBC Type | Protection Against Static | Grounding Required | Suitable For | Not Suitable For |

| Type A | None | No | Non-flammable materials | Flammable powders, gases, vapors |

| Type B | Limited (no propagating brush discharges) | No | Flammable powders (without gases/vapors) | Environments with flammable gases or vapors |

| Type C | Excellent (when grounded) | Yes | Flammable powders + vapors/gases | If grounding is not possible |

| Type D | Excellent (static dissipative) | No | Flammable powders + vapors/gases | Contaminated environments with conductive substances |

Best Practices When Choosing an FIBC Bag

- Understand your product – Is it flammable or non-flammable? Does it generate static?

- Assess the environment – Are there flammable gases, vapors, or dust present?

- Follow safety standards – Refer to IEC 61340-4-4 guidelines for electrostatics and packaging.

- Train workers – Ensure proper handling of bulk bags, especially grounding requirements for Type C FIBCs.

- Partner with trusted manufacturers – Work with certified suppliers who adhere to global quality and safety benchmarks.

Conclusion

Understanding FIBC classification is vital for ensuring safety and efficiency in bulk material handling. While Type A and B bulk bags are suitable for non-hazardous and moderately hazardous environments, Type C and D FIBCs are essential when handling flammable products or working in explosive-prone areas. Choosing the right FIBC bag minimizes risks, ensures compliance with safety standards, and protects both people and materials.

Partner with Umasree Texplast for Safe and Reliable FIBCs

At Umasree Texplast, we specialize in manufacturing high-quality FIBC bulk bags, including Types A, B, C, and D, designed to meet international safety and performance standards. With decades of expertise, we provide customized packaging solutions tailored to your industry needs. Whether you require bulk bags for food, chemicals, fertilizers, or construction materials, we ensure durability, safety, and reliability.

Contact Umasree Texplast today to choose the right FIBC solution for your business and experience packaging excellence.