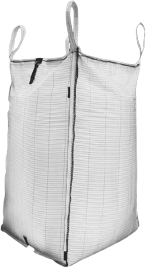

Block Bottom Bags

Ideal for Automated Filling & Packing Cement

Many factors are responsible that affect the quality of cement. Some of them are water ratio, aggregate ratio, temperature, humidity, and so much more. While transporting material, these factors start overwhelming the cement, ultimately you will opt for a packaging material preventing your product from each of these factors. Here is where Block Bottom Cement Bags or Ad* Star Bags plays a vital role. The manufacturing is carried out with coated or BOPP film laminated polypropylene without using any adhesives. Moving ahead let's discuss its types, features, and advantages.

1. Paper Poly Block Bottom Bag

It is a 2 layer bag out of which one layer is laminated with PP outside, while the other with loose craft paper lining inside. This bag is similar to PP bags and has very high moisture resistance and strength. Printing of diverse colors is possible, further as an Ad Star Bags / Block Bottom Bag manufacturer in India, we offer customization options also.

2. BOPP Block Bottom Bag

This bag is designed with BOPP film outside and PP fabric inside, typically used for high-resolution printing required by clients for branding purposes.

- Application: Cement, gypsum, lime, other building materials, also sometimes in food products, chemical industries, and agriculture.

- Shape: Block bottom - Brick shape

- Material: Coated woven PP fabric

- Dimensions and color: Available in standardized and customizable form both

- Type: Valve or open mouth

- Printing: Flexographic or Rotogravure

- Higher Strength: To ensure the strong sacks manufactured have almost zero burst age, we have a personal laboratory where the bags are passed through various tests of dropping, pressing, bending, and so on.

- Maximum Protection: As high-quality woven polypropylene coated fabric is used it assures the product stored or shipped is delivered safely with the utmost protection.

- Space Efficient: Because of its appropriate dimensioning and high stacking, it assists in arranging and utilizing the space during shipping.

- Resists Water & Humidity: High humidity and rough handling is the first advantage a client looks for, and this bag satisfies the needs. Whether it is lying on wet ground or kept under heavy rain, it prevents water and humidity at its finest.

- Environment-friendly

- Cost-effective

- Recyclable and reusable

- Non-fading printing

Umasree Texplast Pvt. Ltd. is widely known as PP Cement Bag Manufacturers in India. If you are a brand or industry of cement and looking for block bottom bags that suits you then feel free to contact us, we are always ready to help you out.

Our AD Star bags plant is located in the city of Jaipur and produced in our sister concern Alliance Polysacks Pvt. Ltd.

Other Suggested FIBC Products