We believe 'Quality Assures Alliances'. It is the benchmark of lasting partnerships. For this very reason, Quality is the epitome of our system. Right from procurement, to manufacturing, to delivery, all the way to aftersales service, we have the values of highest quality imbibed in every facet of our business. From cutting-edge, in-house testing lab to physical quality control by skilled engineers and technicians, all products have to pass through string monitoring phases, to ensure every FIBC from Umasree is as per international standards. One of the biggest strengths of our quality protocols is third party audit. We employ reputed external quality inspectors, who report directly to the top management, thus ensuring that all our processes are always in immaculate conditions. In addition, we also use superior grade polymers and other additive materials combined with our world-class processing technologies, throughout our manufacturing activities.

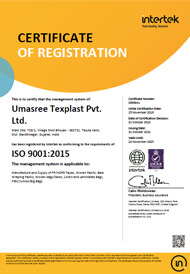

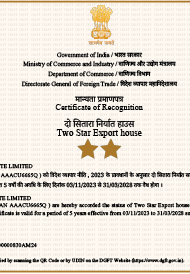

Our judicious methods have earned us numerous accolades from across the world including ISO 22000:2018 certification, Recognition as Export House from Government of India and FIBC Test Certification from Reputed Labs across the Globe.

At Umasree we are consistently driven towards producing consistent quality products while meeting the diverse packaging needs of our clients. All products have to pass through our in-house quality control laboratory under the supervision of trained engineers and lab technicians. These measures ensure tat every single one of our products are of superior quality and as per international standards. Further, the judicious use of superior grade polymers & other additive materials combined with our superior processing technologies, help us deliver market leading range of PP Plastic Woven Sacks & FIBC's.

Anup GopalkaManaging Director

Umasree Texplast Pvt. Ltd.

Stringent Quality Monitoring System

- Quality checking as per pre-defined Quality standards, of all semi-finished goods produced in the Extrusion and Weaving stage.

- In process checking of all components used in the finishing stage i.e. Cutting, Printing and Stitching.

- Full inspection of all bags produced, to ensure bags are produced within the tolerance specified.

- Rig Test of bags to ascertain the load bearing capacity of each bag.

- Random inspection of packed bales ensures audit of the Production & Quality team's performance.

Our Testing Laboratory

A round the clock, in-house quality monitoring facility, equipped with all necessary instruments, enables us co conduct tests spanning all spheres of our production process, from incoming Raw Materials to Finished Bags. Thls helps us to implement stringent quality norms and hence deliver the product within the prescribed tolerance limits.

A few examples of our testing capabilities

| MFI Testing Machine | To check the flow characteristics of the Raw Material granules. |

| Tensile Testing Machines | To check the tensile properties of Tape, Fabric, Belt and Yarn. |

| UV Testing Machine | To check the UV resistance properties of Fabric, Belt and Yarn. |

| Test Rig Machine | To check the load bearing capacity of the FIBC and conduct R&D to improve product quality |