UN Bags are designed to carry hazardous products and their use is regulated by the UN Association, commonly known as the Orange Book.

There are four types of FIBCs for dangerous goods made from woven plastics:

- 13 H 1 - Woven plastics without coating and without liner

- 13 H 2 - Woven plastics, coated and without liner

- 13 H 3 - Woven plastics, uncoated and with liner

- 13 H 4 - Woven plastics, coated and with liner

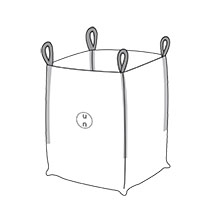

UN Bags are also classified according to the Hazard level of goods they carry. Each UN Bag shall carry the UN-Symbol mentioned in the below table

which shall imply the hazard level of the product.

| Degree Of Danger |

Packing Group |

UN-Symbol |

max. Volume |

| High |

| |

X |

1.5 m3 |

| Medium |

|| |

Y |

3.0 m3 |

| Low |

||| |

Z |

3.0 m3 |

All UN Bags are treated as multi-trip bags even though there is no safety factor 6:1. This term is unknown in the

UN regulations. UN bags are not classified by safety factors. They are instead classified by packing groups I, II or

III. The safety factor 6:1 refers to FIBCs for non-dangerous goods only.

UN Test

Several tests are applied to the UN Certified Big Bags in order to verify UN requirements such as :

Top lift test, Tear test, Stacking test, Drop test, Topple test , Righting test The above tests are conducted by the

certified test houses before they issue the certificates. This report will describe in detail not only the specification of the Fibc tested but the test levels at which the Fibc passed. The certificate is unique to the type of Fibc tested and may only be used to cover the carriage of products within the limit of the UN test.

The options available are as follows:

- SWL Range: 500 kg to 1500 kg

- Fabric: Coated / Uncoated

- Liner: Tubular / Shaped

- 4 Colour Printing

- Various Top and Bottom construction options